Vertix® Systems. Engineered for life

Get A PriceWhat Is a Standing Seam Roof?

A standing seam roof represents a modern and aesthetically pleasing roofing system known for its sleek and minimalist design. Standing seam roofs feature flat panels that connect to each other at raised seams. This structure helps to provide a unique appearance.

The key characteristic of standing seam roofing is that the fixings are concealed, enhancing the roof’s sleek aesthetics and reducing the risk of leaks from potential fixing points.

Types of Standing Seam Roofs

There are two types of standing seam roofs, which include a fully supported standing seam roof and a self-supporting or structural spanning standing seam roof.

Fully Supported Standing Seam Roof

The fully supported standing seam roof is typically fitted directly to a solid substrate, such as plywood or a metal deck. It boasts a wider profile and doesn’t require ribs in the centre, resulting in smaller seams.

Self-supporting or Structural Spanning Standing Seam Roof

The self-supporting standing seam, also known as a structural spanning roof deck standing seam roof, tends to be narrower and features stiffening ribs. The seams on this type are deeper, providing enhanced structural integrity.

You’ll commonly find self-supporting standing seam roofs in applications such as:

- Stadiums: Large sporting venues rely on self-supporting standing seam roofs for their structural stability and durability.

- Sports Halls: These roofs are ideal for sports halls, offering both form and function.

- Airports: Airports require robust roofing solutions to withstand various weather conditions.

- Large Infrastructure Projects: This type of standing seam roof is often used in infrastructure projects that demand long-lasting performance.

- Hospitals: Healthcare institutions benefit from the combination of aesthetics and durability.

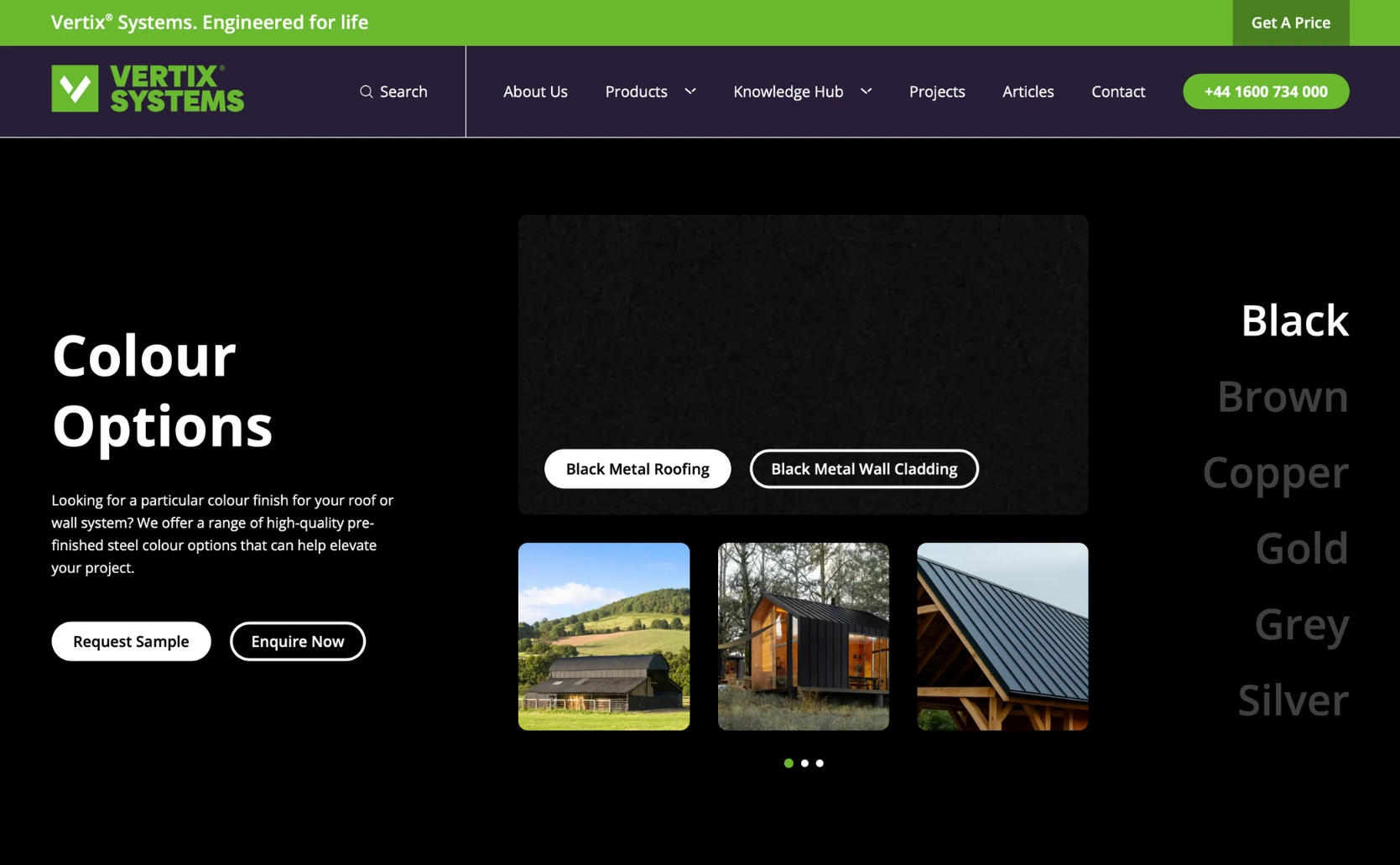

Versatile Material Options

Standing seam roofs are available in various materials, allowing property owners to choose based on their specific needs and preferences. Common materials include:

- Pre-finished Steel: Known for its durability, cost-effectiveness, fire performance. Comes in a wide range of paint options, including polyurethane which has excellent durability and UV stability.

- Stainless Steel: A high-quality option offering both longevity and a sleek appearance.

- Copper: Prized for its unique patina and aesthetic appeal.

- Zinc: A material known for its longevity and corrosion resistance.

- Aluminium: Lightweight and corrosion-resistant.

Seam-Detail and Closing Mechanism

The standing seam system consists of the detail and closing mechanism of a standing seam roof may vary from system to system. Some systems feature a convenient click-and-lock mechanism, while others require manual closure or the use of specialised machinery.

The choice of system and closure method often depends on the specific requirements of the project.

What Are the Benefits of Metal Standing Seam Roofing?

Metal standing seam roofing offers a range of advantages that make it a compelling choice for property owners looking for a durable and aesthetically pleasing roofing solution. Let’s delve into these benefits:

1. Exceptional Durability

Metal standing seam roofs are renowned for their outstanding durability. They can withstand the harshest elements, including heavy wind, rain, intense sunlight, and snow. This resilience ensures a long-lasting roofing solution that can endure the test of time and various weather conditions.

2. Low Maintenance

One of the standout features of metal standing seam roofing is its low maintenance requirements. It’s a “fix and forget” system, meaning once installed, it demands minimal ongoing maintenance. This not only saves time and effort but also reduces the long-term cost of roof care and upkeep.

3. High-End Appearance and Finish

The sleek and modern appearance of metal standing seam roofs sets them apart from traditional metal profile systems. Their clean lines and smooth surfaces create a high-end finish that enhances the aesthetics of any structure. This roofing option offers a contemporary look that is far less industrial, making it a popular choice for a wide range of architectural styles.

4. Longevity

Metal roofs have an impressive lifespan and can last for over 50 years when properly installed and maintained. This longevity is a significant advantage, as it reduces the need for premature roof replacements and the associated costs.

5. Eco-Friendly and Recyclable

Metal standing seam roofs are environmentally friendly. At the end of their life cycle, they are fully recyclable, minimising the impact on landfills and reducing the demand for new raw materials. This eco-conscious feature contributes to sustainability and responsible construction practices.

6. Standard Form of Construction

Metal standing seam roofs are often classified as a standard form of construction. This designation has practical benefits, such as making it easier to secure standard house insurance and a mortgage on the property. It demonstrates the reliability and trustworthiness of this roofing solution.

7. Concealed Fixings

A key design feature of metal standing seam roofs is the concealed or secret fixings. This method not only enhances the overall aesthetics of the roof but also eliminates a potential source of leakage at fixing points. The result is a clean and streamlined appearance that minimises the risk of water infiltration.

8. Energy Efficiency

Metal standing seam roofs offer excellent energy efficiency. They naturally reflect heat back into the environment rather than allowing it to build up inside the building. This means that in the summer, the roof helps keep the interior cooler, while in the winter, it aids in maintaining warmth. As a result, these roofs can significantly reduce heating and cooling energy costs, depending on the season.

What Are the Disadvantages of Standing Seam Metal Roofing?

So – we’ve looked at the benefits of standing seam metal roofing systems. It’s just as important to consider the disadvantages (or potential disadvantages) so you’re able to make an informed decision. Here, we’ll highlight some of the challenges associated with standing seam metal roofing.

1. Installation is Key

As with any roofing system, proper installation is crucial to ensure the performance and longevity of a standing seam metal roof. When installed correctly, many of the potential disadvantages become non-issues. However, overlooking this critical aspect can lead to several challenges.

2. Drumming in High Winds

One concern related to improper installation is the potential for “drumming” during high winds. When a standing seam metal panel or roof is not securely attached, it can create audible noise as the wind passes over the panels. This can be an annoyance and may disrupt the peace and comfort of your living or working space.

3. Rain Noise on Roofs

Another issue associated with installation is the potential for rain noise on roofs that have not been boarded or insulated. If the roof lacks a solid substrate, such as plywood or corrugated metal roofing or deck, the raindrops hitting the metal surface can resonate and become noisy. This is a concern for those seeking a quiet and tranquil environment.

4. Correct Fixings are Essential

The correct fixings must be used at the right frequency to prevent the roof from lifting off during high winds. Properly secured fixings ensure the structural integrity of the roof, protecting it from wind-related issues and potential damage.

5. Wind Load Considerations

To address the issue of wind load, Vertix® Systems provides detailed guidance in its EasySeam® Technical guide. Following this advice ensures that these problems can be greatly reduced or eliminated. Proper wind load calculations and correct installation techniques are essential to mitigate these disadvantages effectively.

6. Oil Canning and Cushioning

Oil canning or cushioning is a natural effect that can occur on metal standing seam roofs. This phenomenon can make the roof look different in the sunlight, appearing wavy or distorted. It’s often a result of thermal expansion in the metal standing seam system. However, addressing this issue is possible, and Vertix® Systems provides guidance in its EasySeam® Technical Guide on how to minimise the appearance of oil canning.

You can download the Technical Guide here.

Is Standing Seam Roofing Right for My Property?

Standing seam roofing is a versatile and aesthetically pleasing choice that can enhance the architectural appeal of your property. However, determining whether it’s the right roofing solution for your specific needs requires careful consideration. Here, we’ll explore the factors that can help you decide if standing seam roofing is a suitable fit for your property.

Versatile Applications

Standing seam metal roofs are celebrated for their adaptability and durability. They are a favourite among town planners and architects for their contemporary and sleek appearance. These roofs are suitable for various applications, including:

New Builds

If you’re constructing a brand-new property, standing seam roofing can provide a fresh and modern look that complements your architectural vision.

Extensions

When extending your existing structure, standing seam roofing seamlessly integrates with your current roof, maintaining a cohesive appearance.

Refurbishments

Updating your property with a roof renovation? Standing seam metal roofing can breathe new life into your structure, transforming it into a modern and eye-catching space.

Standing Seam Roofing & Planning Restrictions

Before opting for a standing seam roofing system, it’s essential to check for specific planning restrictions in your location. While this roofing system is favoured by many, local regulations and architectural guidelines may affect your ability to install it. It’s advisable to consult with local authorities or your architect to ensure compliance with any planning restrictions.

Contemporary Look and Environment Integration

The Vertix EasySeam® roof system, in particular, is renowned for its contemporary appearance. It adds a fresh and sleek aesthetic that can elevate the overall look of your property.

Whether your property is in an urban or rural setting, standing seam roofing can be designed to merge seamlessly with the environment, enhancing the natural beauty of the surroundings.

Can You Walk on a Standing Seam Metal Roof?

One common question that property owners often have about standing seam metal roofs is whether it’s safe to walk on them. The answer depends on several factors and requires careful consideration to ensure both the safety of the roof and those who may need access to it.

Walking on Fully Supported Standing Seam Roofs

A fully supported standing seam roof, being securely fastened to a solid substrate such as plywood or a metal deck, can typically support the weight of a person. However, it’s crucial to exercise caution to prevent any damage to the roof’s surface. Here are some considerations when walking on these roofs:

Debris on Shoes

Be mindful of debris on your shoes, as it can potentially scratch or dent the roofing material. Cleaning your shoes before walking on the roof can help mitigate this risk.

Ageing Roof and Structure

As the roof and its supporting structure age over time, it’s essential to assess their condition periodically. Weather, wear and tear, and other factors can impact the roof’s structural integrity. In some cases, the roof structure may deteriorate to the point where it is no longer safe to walk on.

Safety Hazards

Extreme cases may involve a roof structure that has failed or weakened significantly. In such situations, there’s a real danger of falling through the roof if it’s walked on. Safety should be the top priority, and caution is advised.

Seeking a Professional Assessment Before Standing on a Standing Seam Roof

Given the potential risks associated with walking on standing seam metal roofs, it’s recommended that a professional roofer or structural engineer conduct a thorough assessment of the roof’s condition and safety.

They can determine whether it’s safe to access the roof and, if necessary, recommend reinforcements or repairs to ensure its integrity.

How are Standing Seam Metal Roofs Attached?

Standing seam roofs are attached to the substructure using either fixing clips or nails. Vertix EasySeam® roof system uses nails secured through the nail strip on each panel to connect to the board.

How Long Does a Standing Seam Metal Roof Last?

Metal standing seam roofs are renowned for their exceptional durability, making them a compelling choice for property owners seeking a long-lasting roofing solution.

Standing Seam Metal Roof Structures Can Exceed 50 Years Under Optimal Conditions

Under optimal conditions, metal standing seam roofs can last in excess of 50 years. This remarkable longevity is a testament to the inherent durability of the materials and construction methods used in these roofs. Their ability to withstand various weather conditions and environmental factors contributes to their extended life expectancy.

Painted Metal and Extended Longevity

Many painted metal manufacturers suggest a life expectancy of greater than 40 years for their products. This is a testament to the high-quality finishes applied to the metal panels, which provide protection against corrosion and wear.

Moreover, the life of a painted metal standing seam roof can be further extended through overpainting, ensuring that it remains not only functional but also aesthetically pleasing. Their resistance to various environmental factors, along with proper maintenance, ensures that they provide long-lasting protection for your property.

Environmental Factors Impacting Longevity

While standing seam metal roofs are known for their durability, environmental factors can influence their longevity. Some of these factors include:

- Sunlight: Prolonged exposure to intense sunlight can accelerate the natural ageing of the roofing materials.

- Pollution: Airborne pollutants, such as industrial emissions, can have a corrosive effect on metal surfaces, potentially shortening their lifespan.

- Roof Pitch: The pitch of the roof can impact how water and debris flow, affecting the overall wear and tear on the roofing materials.

- Location: The geographical location of the property also plays a role in the roof’s longevity. In the UK, for instance, metal standing seam roofs in rural, unpolluted inland areas tend to last longer compared to those in coastal areas. Coastal regions are more susceptible to the effects of airborne salt, which can have a more significant impact on the roof’s durability.

How to Measure Standing Seam Metal Roofing

Accurate measurements are fundamental when planning to install a standing seam metal roof. These measurements serve as the foundation for pricing, materials ordering, and the overall success of your roofing project.

Here’s how to effectively measure standing seam metal roofing:

Detailed Drawings or Roof Dimensions

Most metal standing seam manufacturers rely on either detailed drawings or precise roof dimensions provided by the customer to determine the pricing and material requirements for the project. These measurements typically encompass the following key elements:

- Roof Pitch: The pitch of the roof is the angle at which it slopes. Accurately measuring the pitch ensures that the standing seam metal panels will fit properly and that the system will function as intended.

- Rafter Length Including the Fascia: Measuring the length of the rafters, including the fascia, is vital to determine the quantity and dimensions of the metal panels required.

- Width of the Elevation: The width of the elevation refers to the horizontal dimension of the area that the metal panels will cover. This measurement is essential for calculating the necessary materials and pricing.

Vertix Systems Price Enquiry Form

For those considering Vertix EasySeam® standing seam metal roofing solution, a convenient price enquiry form is available. This form can be downloaded from their website and clearly specifies the dimensions and other essential information needed to provide an accurate price quote.

Download our price enquiry form here.

Emailing Drawings for Price Requests

Alternatively, customers can send their detailed drawings and specifications to info@vertix.systems to request a price quote. This method allows for direct communication with the manufacturer and ensures that the project’s unique requirements are taken into account.

How Do You Repair a Standing Seam Metal Roof?

Individual panels on a metal standing seam roof system can be replaced if they become damaged, but because of the durability of this type of system, the roof should not require repairing during its life. They can also be over-sprayed with paint to extend their life further. Individual panels of the Vertix EasySeam® Roof System can easily be replaced.

Building owners may also want to add or remove roof lights and soil vent pipes during the roof’s life. In each of these cases, replacement metal standing seam panels can be fitted, avoiding the need for patch panels.

How wide is standing seam metal roofing?

In the UK, metal standing seams are no wider than 500mm because of wind loading conditions in the UK, which can be more extreme than in other parts of Europe, due to our proximity to the Atlantic Ocean.

Vertix EasySeam® Roof System can be supplied in narrower widths or with a stiffening rib in the profile for more exposed locations and high-up roofs. More detailed guidance is available in the Vertix EasySeam® Roof System Technical Guide.

Download the price enquiry form here.

Is a Standing Seam Roof Worth the Money?

Metal standing seams can be a cost-effective alternative to other roofing materials such as slates, tiles and felt membranes. As well as being much quicker to install, reducing fixing costs, supply costs for some metal standing seam systems, such as those made from pre-finished steel, are in line with other material costs.

There are many different materials used in metal standing seam roofs, such as pre-finished steel, stainless steel, aluminium, copper and zinc. The most cost-effective of these is pre-finished steel, which can last for a similar length of time to the other materials.

An important factor to consider when choosing which metal standing seam system to use is the level of skill required for installation. Some systems are more complex and can only be installed by trained professionals. Others, like the Vertix EasySeam® Roof System, are much easier, reducing the level of skill required.

Can You Put a Standing Seam Metal Roof Over the Shingles?

The best practice is to strip the shingle roof back to the board and check its condition. If the boarded substrate shows rot, it may require repair or replacement before the metal standing seam roof can be installed.

Also, if the building owner wants to increase or add insulation layers to the roof, then checks will need to be made to see if ventilation or a vapour control layer is required to minimise condensation.

Vertix® Systems provides detailed guidance on condensation in its EasySeam® Technical Guide, and following advice will ensure this can be eliminated.

Download our price enquiry form here.

Can You Reuse a Standing Seam Metal Roof?

This will depend on the individual metal standing seam system and material used. For example, systems that use a welted-down top standing seam panel, such as zinc standing seam roofing, cannot be reused.

Vertix EasySeam® Roof System can be unclipped and re-used, and because there are no fixings through the panel itself, this remains undamaged. In these situations, customers may sometimes put the standing seam roof on a temporary building, lift it off and move it to a permanent building at some point in the future.

Can Zinc-Standing Seam Roofs Be Used in Green Roofs?

No. You would not put a green roof on a low-pitch metal standing seam roof where the trays holding the water are above the seam. This can potentially cause the roof to leak through the seams.

Do Standing Seam Metal Roofs Leak?

Standing seam metal roofs are renowned for their durability and resistance to leaks, but like any traditional roofing materials or system, they may still encounter potential issues. Here, we’ll explore some of the factors that can influence the occurrence of leaks in standing seam metal roofs.

Condensation Concerns

Condensation can be a challenge for all types of roofs, including standing seam metal roofs. It occurs when moisture in the air condenses on the underside of the roof, potentially leading to water-related problems. Several factors can contribute to condensation, such as:

Inadequate Ventilation

A lack of proper ventilation can lead to moisture buildup, especially when the building’s occupants produce water vapour through their activities. Adequate ventilation is essential to address this issue and prevent condensation-related problems.

Penetrations and Detailing

The quality of the detailing and penetrations on the roof can also influence leak potential. If not done correctly, these areas can become vulnerable points for water infiltration. Proper sealing and attention to detail during installation are essential to minimise the risk of leaks.

Ponding Due to Low Roof Pitch

A roof pitch of less than 5 degrees can lead to ponding. This occurs when water collects in ponds on the roof’s surface after a period of heavy rain and does not drain off once the rain has stopped. Ponding can create the risk of leaks and affect the roof’s overall performance.

Vertix Systems provides detailed guidance on condensation and detailing of penetrations in our EasySeam® Technical Guide.

Download the price enquiry form here.

How Thick Is Standing Seam Metal Roofing?

The gauge of metal standing seam systems is dependent on the material used. Typically, it will be between 0.6mm and 0.9mm thick.

Vertix Systems uses 0.675 mm pre-finished steel for its EasySeam® roof system. This is the thickness of the steel and galvanised layer. With the paint layer on top of this thickness, the nominal gauge is 0.7mm.

How Do You Clean a Metal Standing Seam Roof?

Metal standing seam roofs can be cleaned with a mild detergent and water. Specialist cleaners are also available to remove stubborn stains.

Solvent-based cleaners should not be used. More detailed advice should be sought from the individual metal standing seam manufacturer.

Standing Seam Roofing Prices & Quotes

Prices for metal standing seam systems will vary depending on the material used (e.g. copper, zinc, aluminium, stainless steel and pre-finished steel) and whether the roof is supplied as an individual sheet or system, which includes flashings and ancillaries.

Contact us at info@vertix.systems to request a price bespoke to your requirements today!

Latest News

Take a look at the latest news from Vertix Systems