Vertix® Systems. Engineered for life

Get A PriceThe Best Flat Roof Material for Long-Lasting Protection

Discover the best flat roof materials

Whether you are looking to replace a roof on an existing property, or deciding on what roof to use on a new-build property, it makes sense to take the time to research the best material in the market for flat and low pitch roofs.

With such an abundance of different materials to choose from, this article will explore some of the best roof materials for flat and low pitch roofs available today, to allow you to make an informed decision.

We will be assessing roofing material based on:

- Budget: How much are you thinking of spending, and will it be sufficient for considering a roofing option with a longer lifespan?

- Timeframe: How soon do you want the roof to be installed?

- Climate: Is the roof going to face heavy rain, freezing temperatures or intense sunlight?

- Installer: Are you planning to do it yourself, or will you be hiring a roofing contractor for the job?

Kinds of Materials for Flat and Low Pitch Roofs

Metal Standing Seam

Metal standing seam roofs feature flat panels that connect to each other at raised seams. This structure helps to provide a unique appearance. The key characteristic of a metal standing seam roof is the concealed fixings, enhancing the roof’s sleek aesthetics and reducing the risk of leaks from potential fixing points. This type of roofing material requires a minimum pitch of 5 degrees. This will achieve a slight slope to ensure water run-off and prevent ponding which can compromise the durability of the roof over time.

There are two types of metal standing seam roofs:-

Fully supported

These are typically fitted directly to a solid substrate, such as plywood or a metal deck. It boasts a wider profile and doesn’t require ribs in the centre, resulting in smaller seams. and fully supported. They are commonly used on residential applications.

Self supporting

Also known as a structural spanning standing seam roof, which are often narrower and feature stiffening ribs. The seams on this type of standing seam roof are deeper, providing enhanced structural integrity and tend not to be used for residential applications.

Durability and Longevity

Metal standing seam roofs are extremely durable and can last in excess of 50 years with correct attention to the material manufacturer’s guide regarding maintenance.

Installation Difficulty

Fully supported metal standing seam roofs are relatively straightforward to install for a very experienced DIYer but are most commonly fitted by a roofing professional.

Design/Aesthetics

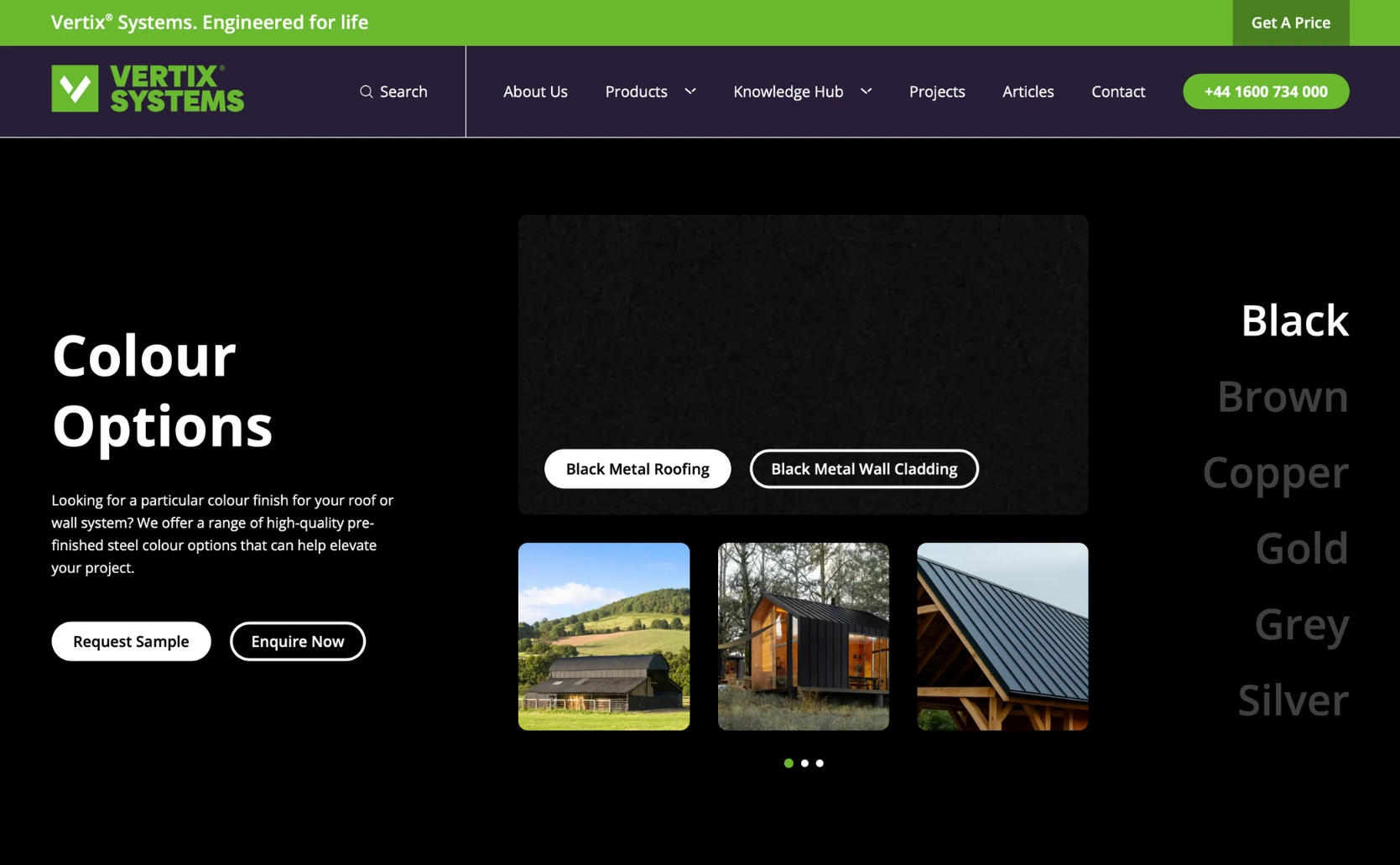

Metal standing seam roofs, particularly those manufactured in pre-finished steel or painted aluminium, are available in a wide range of colours with matt and gloss finishes.

Average Cost

The cost of a metal standing seam roof depends on the metal being used and the size of the roof. Zinc, copper, aluminium and stainless steel are more expensive materials than pre-finished steel (painted steel). As an average, supply and installed metal standing seam roofs can range from £80 per square metre for a pre-finished steel standing seam roof panel with flashings ranging from £120-£200 per square metre for a zinc or copper version.

Advantages

- Highly durable and can withstand elements such as wind, rain, sunlight and snow.

- It is a fix and forget system that requires minimal ongoing maintenance. A metal standing seam roof can last in excess of 50 years.

- Metal standing seam roofs are recyclable at the end of their life.

- Concealed fixings / Secret fixings help to improve aesthetics and remove potential leakage at fixing points.

- Metal standing seam roofs naturally reflect heat back into the environment instead of allowing it to build up inside the building, which delivers a cooler environment in the summer and warmer during the winter periods. This can help to reduce heating/cooling energy costs depending on the time of year.

- Damaged roof sheets can easily be replaced.

Disadvantages:

- Tend to have a higher upfront cost compared to traditional asphalt shingle or felt roofs, however, this can be off-set by their long lifespan.

- It can be noisy during heavy rain or hailstones, although when mounted on a wood board and properly insulated, noise can be significantly reduced by an RW value of 45DB.

If you’re looking for more info on what a metal standing seam roof is check out our dedicated article.

Roof Felt

Roof felt, also known as bitumen felt or tar paper, is a flexible and waterproof material used to cover flat roofs. It is made from a base material, such as polyester or fibreglass, coated with bitumen (a viscous mixture of hydrocarbons).

Roof felt is commonly used for residential and commercial flat roofs, especially in temporary or budget-conscious applications. It’s ideal for sheds, outbuildings, and temporary structures where cost-effectiveness is a priority.

Durability and Longevity

Roof felt is relatively durable and can provide reliable waterproofing for up to 10-20 years, depending on the quality of the material and installation. However, it may deteriorate more quickly in harsh weather conditions or with poor maintenance. In general, the durability increases with the number of layers applied i.e 1 layer = 10 years , 2 layers = 20 years and 3 layers = 30 years.

Installation Difficulty

Torch on roof felt can be difficult to install even for experienced DIYers and generally requires a professional to install it properly. It typically requires cutting the material to size, securing it to the roof substrate with nails or adhesive, and overlapping seams to ensure waterproofing.

Design/Aesthetics

Roof felt is available in various colours and finishes, including mineral granules or plain black. While it may not offer the aesthetic appeal of other roofing materials, it can be suitable for utilitarian or functional applications.

Average Cost

The cost of roof felt varies depending on the quality and thickness of the material, as well as the size of the roof. On average, roofing felt can range from £30 to £60 per roll (10m x 1m). Supply and installation for a 3 layer felt system would be over £100 per square metre.

Advantages

- Cost-effective option for flat roof coverings.

- Provides basic waterproofing and protection against the elements.

- Can be installed relatively quickly and with minimal equipment.

Fully adhered to the board torch on felt is very robust when compared with other roofing membranes.

Disadvantages

- Limited lifespan compared with other flat roof materials.

- Susceptible to damage from UV exposure, temperature fluctuations, and mechanical stress.

- May require regular maintenance and repairs to prolong lifespan.

Types of Roof Felt:

- Torch-on Felt: Torch-on felt is a type of roofing felt that is applied using heat to activate the adhesive backing. It offers improved waterproofing and durability compared to traditional roofing felt and is commonly used in professional roofing installations.

- Shed Felt: Shed felt is a lightweight and cost-effective option specifically designed for small-scale applications such as garden sheds, playhouses, and outbuildings. It provides basic waterproofing and protection against the elements.

Flat Roof Trims:

Flat roof trims, also known as edge trims or drip edges, are essential components used to finish and protect the edges of flat roofs. They help to create a neat and watertight finish while preventing water ingress and damage to the roof structure.

Flat roof trims come in various materials, including aluminium, PVC, and stainless steel, and are available in different profiles to suit different roof configurations. Installation typically involves fixing the trims to the perimeter of the roof using screws or adhesive, ensuring a secure and weatherproof seal.

EPDM Roofing

EPDM (ethylene propylene diene monomer) roofing is a synthetic rubber membrane widely used for flat roofs. It is composed of a durable rubber compound that provides excellent waterproofing and weather resistance.

EPDM roofing is suitable for a wide range of applications, including residential, commercial, and industrial buildings. It is commonly used for flat and low-slope roofs, as well as for covering extensions, garages, and outbuildings.

Durability and Longevity

This kind of roofing is known for its exceptional durability and longevity. When correctly installed and maintained, EPDM roofs can last upwards of 30 years or more. The rubber membrane is resistant to UV radiation, ozone, and weathering, making it a reliable choice for long-term protection.

Installation Difficulty

EPDM roofing installation requires careful preparation and attention to detail but can be completed by DIY enthusiasts or professional roofers. The membrane is typically fixed to the roof substrate using adhesive or mechanical fasteners, with seams sealed using special tapes or adhesives.

Design/Aesthetics

EPDM roofing is available in black or white colours, with the option for reinforced membranes for added strength. Whilst not as visually appealing as other roofing materials, EPDM provides a clean and modern finish suitable for a wide range of architectural styles.

Average Cost

The cost of EPDM roofing varies depending on factors such as the size of the roof, thickness of the membrane, and complexity of the installation. On average, EPDM roofing materials can range from £15 to £30 per square metre

Advantages

- Excellent waterproofing and weather resistance.

- High durability and longevity, with a lifespan of 30 years or more.

- Flexible and lightweight material that can accommodate building movement.

- Low maintenance requirements and easy to repair if damaged.

Disadvantages

- Lacks robustness and is vulnerable to punctures from sharp objects or foot traffic.

- Limited aesthetic options compared to other roofing materials.

- Requires careful installation to ensure proper sealing and waterproofing.

- May be more expensive upfront compared to traditional roofing materials.

Types of EPDM Roofing Material:

- EPDM Membrane: The EPDM membrane is the primary component of the roofing system, providing waterproofing and weather protection. It is available in various thicknesses and sizes to accommodate different roof configurations.

- EPDM Outlets: EPDM roof outlets are used to provide drainage for flat roofs, directing rainwater away from the roof surface, preventing pooling. They are available in various designs, including scuppers, drains, and gutters, to suit different installation requirements.

- Adhesive & Primer: Adhesive and primer are essential for securing the EPDM membrane to the roof substrate. The adhesive creates a strong bond between the membrane and the roof surface, while the primer improves adhesion and ensures proper sealing of seams and edges.

- EPDM Tapes: EPDM tapes are used to seal seams, joints, and edges of the membrane, providing additional waterproofing and reinforcement. They are available in different widths and thicknesses to accommodate various installation requirements.

- EPDM Trims: EPDM trims, also known as edge trims or termination bars, are used to finish and protect the edges of the EPDM membrane. They provide a neat and watertight seal, preventing water ingress and damage to the roof structure. Trims are available in various materials and profiles to suit different roof configurations.

GRP Roofing

GRP (Glass Reinforced Plastic) roofing, also known as fibreglass roofing, is a lightweight and durable roofing material made from a combination of polyester resin and glass fibres. It is manufactured by layering the fibreglass matting with resin to create a strong and waterproof membrane.

GRP roofing can be used for flat and low-pitch roofs, including extensions, balconies, and garage roofs. It can be a good choice for properties in coastal areas where the weather conditions can be harsher.

Durability and Longevity

Renowned for its robustness and longevity, GRP roofing boasts a commendable lifespan when installed and maintained with care. Resistant to corrosion, UV radiation, and weathering, it stands up well to exposure in challenging environments. With regular maintenance, GRP roofs can endure for over 30 years.

Installation Difficulty

Installing a GRP roof demands meticulous preparation and attention to detail. However, both DIY enthusiasts and professional roofers can undertake the task. The process entails the application of layers of fibreglass matting and resin onto the roof substrate, resulting in a seamless and waterproof finish.

Design/Aesthetics

GRP roofing offers versatility in terms of finishes, ranging from smooth to textured surfaces, catering to diverse aesthetic preferences. While it may not possess the visual allure of some other roofing materials, GRP imparts a clean and contemporary appearance, perfectly suited to modern buildings.

Average Cost

The cost of GRP roofing depends on factors such as the size of the roof, the complexity of the installation, and any additional features or accessories required. On average, GRP roofing materials can range from £30 to £60 per square meter.

Advantages

- Excellent waterproofing and weather resistance.

- High durability and longevity, with a lifespan of 30 years or more.

- Lightweight material that is easy to transport and handle.

- Seamless installation that eliminates the risk of leaks and water ingress.

Disadvantages

- Requires specialised knowledge and skills for correct installation.

- It can be more expensive upfront compared to traditional roofing materials.

- Limited aesthetic options compared to other roofing materials.

- Susceptible to damage from foot traffic or impact.

Types of GRP Roofing Material:

- Standard GRP Roofing: Standard GRP roofing consists of multiple layers of fibreglass matting and resin applied to the roof substrate. It provides excellent waterproofing and durability, making it suitable for a wide range of applications.

- Fire-Retardant GRP Roofing: Fire-retardant GRP roofing incorporates additives to improve fire resistance, making it suitable for buildings with strict fire safety requirements. It offers the same benefits as standard GRP roofing with enhanced fire protection.

- Anti-Slip GRP Roofing: Anti-slip GRP roofing features a textured surface to provide additional grip and traction, making it suitable for walkways, balconies, and other areas with high foot traffic. It helps to improve safety and prevent accidents caused by slippery surfaces.

- Coloured GRP Roofing: Coloured GRP roofing is available in a variety of hues to match or complement the aesthetic of the building. It allows for customisation and personalisation of the roof’s appearance, adding visual interest and curb appeal.

Green Roofs

Green roofs, also known as living roofs or eco-roofs, are roof systems that are partially or completely covered with vegetation, soil, and other greenery. They consist of several layers, including a waterproofing membrane, drainage layer, growing medium, and vegetation, creating a natural habitat for plants and wildlife.

This roof type is typically used in urban environments to mitigate the adverse effects of development, such as urban heat island effect, stormwater runoff, and air pollution. Green roofs are ideal for commercial, residential, and institutional buildings, as well as for retrofitting existing structures to improve sustainability and environmental performance.

Durability and Longevity

Green roofs are durable and can last for decades when correctly designed, installed, and maintained. The waterproofing membrane and drainage layers provide protection against water ingress and root penetration, whilst the vegetation helps to regulate temperature and reduce solar heat gain. With regular maintenance, green roofs can contribute to the longevity of the underlying roof structure.

Installation Difficulty

Installing a green roof requires careful planning, expertise, and coordination among various trades, including roofing contractors, landscapers, and irrigation specialists. The process involves installing layers of waterproofing membrane, drainage matting, growing medium, and vegetation, followed by irrigation and maintenance systems. While it can be a complex and labour-intensive process, professional installation ensures optimal performance and longevity.

Design/Aesthetics

Green roofs offer a unique and visually striking aesthetic, blending seamlessly with the natural landscape and surrounding environment. They can be designed to replicate natural ecosystems with a diverse range of plant species, colours, and textures. Green roofs also provide opportunities for creative expression and customisation, allowing for the incorporation of features such as rooftop gardens, pathways, and seating areas.

Average Cost

The cost of green roofs varies depending on factors such as the size of the roof, type of vegetation, and complexity of the installation. On average, green roofs can range from £50 to £200 per square metre, including materials and installation.

Advantages:

- Help to improve air quality, reduce the urban heat island effect, and provide habitat for wildlife.

- Help insulate buildings, reducing heating and cooling costs, and extending the lifespan of the roof membrane.

- Absorb and retain rainwater, reducing stormwater runoff and alleviating pressure on drainage systems.

- Can enhance the visual appearance of buildings, adding green space and biodiversity to urban areas.

Disadvantages:

- It can be expensive to install compared with traditional roofing systems, requiring additional materials and labour.

- Require regular upkeep, including watering, weeding, fertilising, and pruning, to ensure the health and vitality of the vegetation.

- Add weight to buildings, requiring careful engineering and structural reinforcement to support the additional load.

- May not be suitable for all buildings or climates, requiring consideration of factors such as roof pitch, exposure and access.

Summary

In this comprehensive guide, we’ve explored various materials for flat and low-pitch roofs to help you make an informed decision about long-lasting protection.

But which is the best material for flat or low-pitch roofs? This depends on your needs and circumstances. Here are some of the key points to consider:

- Metal standing seam: Very durable option that offers a modern and contemporary appearance and good sustainability credentials. Ideal for a wide range of applications in both new build and refurbishment.

- Roof Felt: A cost-effective option suitable for temporary or budget-conscious projects, offering basic waterproofing and protection. Ideal for sheds, outbuildings, and temporary structures.

- EPDM Roofing: Renowned for its durability and longevity, EPDM roofing is a versatile choice suitable for residential, commercial, and industrial applications. It provides excellent waterproofing and weather resistance, making it ideal for areas with high foot traffic or exposure to harsh weather conditions.

- GRP Roofing: Combining strength, durability, and versatility, GRP roofing offers exceptional performance in challenging environments. It is highly resistant to corrosion, UV radiation, and weathering, making it suitable for flat and low-pitch roofs, extensions and balconies.

- Green Roofs: Embracing sustainability and environmental stewardship, green roofs offer a myriad of benefits, including improved air quality, energy efficiency, and stormwater management. They provide habitat for wildlife, reduce urban heat island effect, and enhance the visual appeal of buildings.

Whether you are considering a roof replacement or planning a new construction project, it is essential to choose the right flat roof material for your specific needs. Vertix® Systems can offer advice and guidance on the best solution for your flat or low pitch roof project. Get in touch with us today.

Latest News

Take a look at the latest news from Vertix Systems